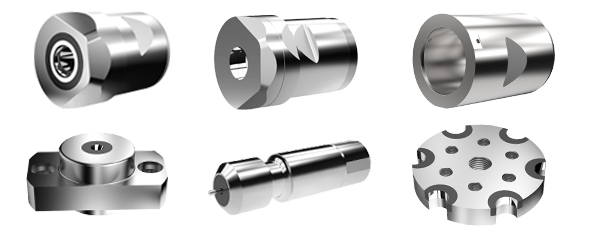

Fastener Tooling (Extrusion/ Trap Extrusion Dies / Punches) Manufacturer, Supplier

In the ever-evolving fasteners industry, Parin Engineering stands as a beacon of excellence, offering a comprehensive range of high-quality carbide tools and tooling solutions. Our commitment to delivering top-notch tooling for the fasteners industry has earned us a well-deserved reputation as a leading manufacturer and supplier.

Serving the Fasteners IndustryParin Engineering specializes in manufacturing heading dies, a critical component in the production of various fasteners such as headed screws, rivets, pop-up rivets, bolts, nuts, and more. Our precision-crafted carbide tools cater to the diverse needs of the fasteners industry, enabling our clients to meet their specific manufacturing requirements effectively. With years of experience under our belt, we've become a trusted partner, helping our customers in the fasteners industry achieve the right product for their applications.

The Power of Cold Heading TechnologyAt Parin Engineering , we harness the advantages of cutting-edge cold heading technology, offering unmatched benefits for fastener manufacturing. This technology boasts higher production rates, ensuring your production lines stay efficient and cost-effective. One of the key advantages is that it preserves the properties of the base material, eliminating any compromise in material quality. Additionally, cold heading provides a superior finish, enhancing the overall appearance and functionality of the fasteners produced.

Comprehensive Housing SolutionsIn addition to our world-class carbide tools, we also manufacture housing components compatible with a variety of machinery, including renowned models such as CHUN ZU and SACMA. We understand the urgency of the fasteners industry and maintain a substantial inventory of housing sizes, ready to be dispatched within a mere 1-2 days. This swift response minimizes downtime and ensures uninterrupted operations for your business.

Diverse Range of Carbide Tool Profiles Our extensive product portfolio includes a wide array of carbide tool profiles designed to meet the unique demands of fastener manufacturing. These profiles encompass:

• Extrusion Dies: Ideal for shaping fasteners with extruded features.

• Pointing Dies: Essential for forming pointed ends on fasteners.

• Trap Extrusion Dies: Perfect for creating trap extrusions in fasteners.

• Countersunk Dies: Tailored for producing countersunk fasteners.

• Washer Face Dies: Ensuring fasteners with washer faces are manufactured to perfection.

For more specialized requirements, we offer precision-crafted special carbide dies with hexagon profiles.

Parin Engineering manufactures all types of heading dies suitable for Fastener Industries. These are used for manufacturing headed screw, rivets, Pop up rivets, Bolts, Nuts, etc in different material. We cater to complete solution for fastener tooling from Design, Manufacturing and Execution. Our years of experience has helped our customers in getting the right product for all their applications

The advantages of cold heading over conventional method are higher production rate. There is no change in the properties of the base material, no loss of material. It also gives a better finish.

We also manufacture housing for various machines such as CHUN ZU, SACMA etc. Most of the sizes are in stock and can be supplied within 1-2 days.

The various types of profile such has Extrusion, Pointing, Trap Extrusion, Countersunk, Washer Face, etc are some of the regularly manufactured products. Special dies with hexagon profiles can also be delivered with good precision.