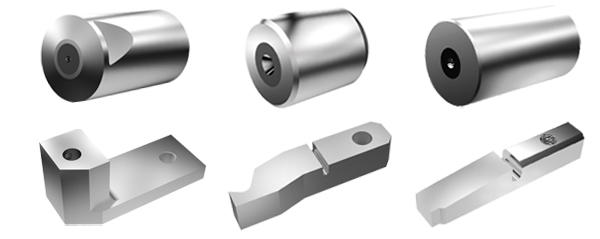

Carbide Cutter / Quill and Finger Manufacturer, Supplier

At Parin Engineering , we take pride in being your trusted source for top-notch carbide cutter, Carbide Quill, and Carbide Fingersolutions. Our products play a crucial role in the precision cutting of slugs and their seamless positioning between the die and the punch. With a strong commitment to excellence and customer satisfaction, we have earned accolades for our exceptional heading dies and received glowing recommendations from our valued clientele.

Innovative Carbide Solutions for Diverse ApplicationsOur journey into manufacturing Carbide cutters, Carbide Quills, and Carbide Fingers has been driven by our dedication to continuous improvement. We understand that different applications demand different levels of performance, which is why we have developed a range of carbide grades tailored to meet your specific needs. These cutting-edge tools are not only ideal for heading dies but also find applications in the fasteners industry.

Quality Assurance Through Rigorous Process ControlAt Parin Engineering , quality is at the heart of everything we do. Our tools are crafted with meticulous attention to detail, adhering to stringent process controls. We are proud to offer 100% traceability of the carbides used in each die, ensuring transparency and accountability in our manufacturing process.

Swift Delivery with Ample InventoryWe understand the importance of timely deliveries in today's fast-paced industry. To cater to this need, we maintain a substantial inventory of fast-moving items. This strategic initiative significantly reduces delivery lead times, sometimes even to as low as 24 hours, ensuring you have the tools you need precisely when you need them.

Cutters are used in Combination with quill and Finger to Cut the Slug and position in between the die and the Punch. With the success of Heading dies and customer recommendation Parin Engineering started the development of Cutter, Quills and Finger. Different grades of Carbides have been developed for different application, thereby giving optimum performance of the tools. These tools are also manufactured for fasteners Industries.

All the tools are manufactured with stringent process control and 100% traceability of the carbides used for each die can be achieved.

ERP system maintains the data and analytics for the entire process.

We maintain a decent level of inventory of fast-moving items, which helps in reducing the delivery lead time, and in some cases to as low as 24 Hrs.